CLARK electric forklifts, diesel forklifts or LPG forklifts?

The drive technology plays an important role in the decision to purchase a forklift. The drive that is best suited for your unique application should therefore be identified in advance, so that you will be able to attain a high degree of availability and the highest possible level of efficiency. You should therefore carefully balance the pros and cons of the drive technology in question before you actually decide to go for a particular drive technology.

The following facts can help you make your decision:

-

Internal Combustion-engine forklifts:

-

Application areas

Application areas

LPG forklifts are unconditionally well-suited for use in outdoor areas, but they can also be used for certain indoor applications. In fact, such a forklift is actually the preferred tool of choice for operations that are to be carried out in warehouses where battery charging rooms cannot be installed. Since the LPG bottle can be changed quite quickly, LPG forklifts can, for all intents and purposes, run in an interruption-free manner.

-

Pros

Pros

- Conditionally well-suited for indoor use

- Environment-friendlier than a diesel drive

- Low purchase costs

- Quick loading and a high degree of availability thanks to quick changing of the gas cylinder

- Suitable for 3-shift operations

- Lower fuel costs than diesel forklifts

-

Requirements and drawbacks

Requirements and drawbacks

- Less flexible than an electric forklift

- Stringent fuel storage requirements (fire protection, occupational safety)

-

Our LPG and Diesel Forklifts

Our LPG and Diesel Forklifts

-

Application areas

-

Internal Combustion-engine forklifts:

-

Application areas

Application areas

Certain manufacturers would like to declare the diesel forklift to be dead, but if you take a look at the figures for the last 2-3 years, you will realise that the market for forklifts with internal combustion engines continues to grow. Even in Europe, diesel isn’t dying out - This applies in particular to Germany. The diesel engine has become a lot cleaner ever since the Euro 5 standard was rolled out. The diesel forklift therefore continues to be the weapon of choice for situations involving intensive outdoor applications and challenging operations in the metal industry.

-

Pros

Pros

- High performance

- Secure trips, even on uneven surfaces

- Suitable for 3-shift operations

- Simple fuel-filling operation at the petrol station – No long waiting times for recharging the batteries

- Load-carrying capacities of more than 8000 kg

-

Requirements and drawbacks

Requirements and drawbacks

- Only suitable for outdoor use

- The service life depends on the application, usage and maintenance

- Higher noise emissions compared to an electric forklift

- High environmental pollution

- Higher maintenance and repair costs

-

Conclusion

Conclusion

CLARK diesel and LPG forklifts are characterised by robust, reliable and environment-friendly engines. Thanks to an optimal placement of the centre of gravity and fair maintenance and service prices, CLARK’s internal combustion-engine forklifts can offer the optimal solution for any application. With load-carrying capacities ranging from 1500 to 8000 kg and numerous options, we ensure that you always get the truck that is correct for your operating conditions. In this regard, the purchase costs of LPG forklifts are basically lower than those of diesel forklifts. However, since diesel forklifts can be refuelled more quickly, their downtimes are very short. Furthermore, the use of LPG forklifts is environment-friendlier than the use of diesel truck.

-

Our Diesel and LPG Forklifts

Our Diesel and LPG Forklifts

-

Application areas

-

Electric Forklifts:

-

Application areas

Application areas

An electrically-driven forklift is the weapon of choice in situations involving internal transport and movement-of-goods operations that are to be carried out within a production hall or warehouse. Thanks to their compact structure, electric forklifts are particularly well-suited for applications in which space is a critical factor. However, electric forklifts can also serve as an alternative to internal combustion-engine forklifts in outdoor areas. They can safely and quickly transport loads over long distances. Thanks to their modern drive and battery technologies, these silent machines also do their work in an environment-friendly manner. This essentially means that such forklifts are ideally suited to be used in mixed-use zones.

-

Pros

Pros

- Environment-friendly and emission-free operations – There are no CO2 emissions or noise emissions

- Performance that is on a par with that of an internal combustion-engine diesel or LPG forklift, in conjunction with significantly lower operating costs, e.g. savings in maintenance on account of a lower number of moving parts

- Long battery service life

- Low maintenance costs – e.g. no fuel storage requirements

- Flexible handling

-

Requirements and drawbacks

Requirements and drawbacks

- Charging station and a suitable charging location must be available

- The battery service life depends on the application, usage and maintenance

- Provision of a replacement battery for multi-shift usage

- Battery-changing device must be available

- If no replacement battery is provided, it would take some time to charge the battery

-

Conclusion

Conclusion

CLARK’s electric forklifts are often the best choice for operations in smaller warehouses with tight space conditions. In comparison with those who go for a diesel or LPG forklift, customers who choose an electric forklift can benefit from a machine that offers pollutant-free and silent operations, as well as performance that is on a par with that of a diesel or LPG forklift. CLARK’s electrically-driven forklifts are therefore ideally suited for outdoor use in mixed-use zones. Thanks to the associated maintenance savings and low level of energy consumption, CLARK’s electric forklifts don’t just offer long operating times, a high degree of reliability and driving characteristics that can be adapted to the respective application - Their operating costs are also lower than those of internal combustion-engine forklifts.

-

Our Electric Forklifts

Our Electric Forklifts

-

Application areas

-

Electric Forklifts with Li-ion battery:

By changing the recharging behaviour of vehicles with Li-Ion batteries, you significantly and substantially reduce the effort around the battery!-

Energy efficiency

Energy efficiency

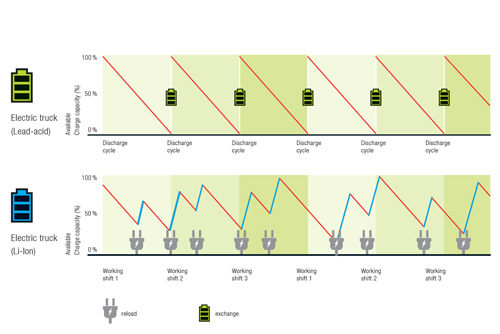

Thanks to the high energy efficiency of the Li-Ion battery, which is guaranteed by perfect energy management, you can use your materials handling vehicles continuously and at the same time, save the effort required for example for a battery change. As shown in the illustration above for a multi-shift operation, charging processes can take place during short breaks in use.

-

Quick and opportunity charging

Quick and opportunity charging

In contrast to the lead-acid battery, which needs 8 to 10 hours for a charging process, with Li-Ion technology and the possibility of flexible quick and opportunity charging, you can avoid battery changes and thus downtimes.

The advantage of Li-Ion technology: a lot of energy is absorbed in a short time. That means 60 minutes of recharging produces a good 100 minutes or more of use.

-

Use of several vehicles

Use of several vehicles

When several vehicles are used, short intermediate stops can also be staggered so that one vehicle is always available and ready for use. During the night, all vehicles can be fully charged as usual and are available at the beginning of the shift, charged and ready for operation - without time-consuming water refilling or further maintenance work around the battery.

-

Flexible charging strategy

Flexible charging strategy

Especially customers with intensive applications benefit from the flexible charging strategy of the Li-Ion battery. For operations in multi-shift operation in distribution and industry or also in the food, beverage and pharmaceutical industries, where clean operation is essential, CLARK electric forklifts with Li-Ion battery are an indispensable component to increase the efficiency of your operation.

-

Energy efficiency