Electric three-wheel forklift

Super elastic tyres

Capacity: 1600 - 2000 kg @ 500 mm LC

STE16/18/20

Overview

The CLARK STE16/20 series: Performance, safety and ergonomics

The CLARK STE16-20 series electric forklift trucks offer outstanding performance, maximum safety and excellent ergonomics. These electric counterbalance trucks ensure smooth logistics processes - and are completely emission-free.

With our advanced SMART display, which informs the operator of all important driving parameters, the two powerful, low-noise drive motors and a design that is built to last, the STE16-20 models represent the next generation of electric forklift trucks - and this generation is SMART, STRONG and SAFE.

| Load capacity | max. 2000 kg @500 mm LSA |

Drive motor power | 2x 4,4kW |

| Lifting height | max. 7075mm | Battery performance (lead-acid version) |

max. 625 Ah |

| Driving speed | max. 15 km/h | Battery performance (lithium-ion version) |

max. 460 Ah |

Features

An optimised arrangement of chains and hoses allows a clear view of the forks and the load. The perfect arrangement of the protective roof struts allows an excellent view upwards.

The driving parameters can be individually programmed via the 5-inch SMART display. When using a reversing camera, the image is transmitted to the colour display. This gives the driver an optimum view of the activities on his route when reversing.

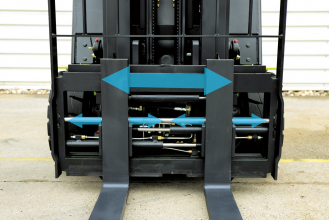

Control levers mounted on the bonnet are available as standard. With up to five hydraulic functions, the use of different attachments is possible.

The nested mast profiles give the operator a wide field of vision. This provides excellent visibility of the load. When driving straight ahead, the large, unobstructed window also increases safety.

Ergonomic mini levers for hydraulic control are available. The mini-levers can be integrated into the direction of travel change on request.

With predictable directional control function on the hydraulic lever, there is no need for the operator to “reach around” to change direction.

Highlights

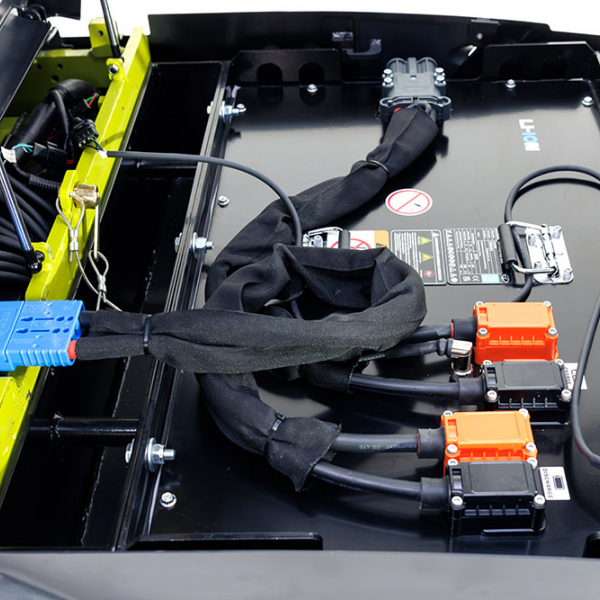

Lithium-ion technology from CLARK

Li-Ion technology: Full power with long battery life and heavy-duty applications

The CLARK electric forklift trucks in the STE16/18/20 series with Li-ion battery ensure efficient goods transport with maximum availability thanks to extremely short charging times and maximum productivity. The maintenance-free Li-ion technology extends battery life, reduces operating costs and enables flexible multi-shift operation thanks to intermediate and fast charging capability.

You save time and optimise your storage space without having to change batteries at the side. And best of all, if your operating conditions change, you can switch back to lead acid technology at any time. Thanks to this high level of flexibility, you can efficiently map any application profile.

Safety features

Numerous safety features speak in favour of the S-Series Electric, as they not only ensure safe and productive use, but also a low total cost of ownership.

CLARK VMS-System

When the function is activated, the tilting process of the mast stops automatically in the vertical position.

Load weight indicator in the display

Informs the driver of the current weight of the load on the forks. Can be combined with other attachments.

Optional equipment

Technical Specification

| Load capacity kg | Height above protective roof mm | Total width mm | Lifting height from/to mm | Aisle width with pallet 800 x 1200 lengthwise (mm) | Travel speed with/without load (km/h) | Battery voltage/ max. rated capacity | |

|---|---|---|---|---|---|---|---|

| STE16 | 1600 | 2066 | 1059 | 2545/7075 | 3358 | 15/15 | 48V, 500 Ah, (48V, 460 Ah) |

| STE18 | 1800 | 2066 | 1059 | 2545/7075 | 3466 | 15/15 | 48V, 625 Ah, (48V, 460 Ah) |

| STE20 | 2000 | 2066 | 1122 | 2545/7075 | 3506 | 15/15 | 48V, 625 Ah, (48V, 460 Ah) |

Produktvideo

Gallery