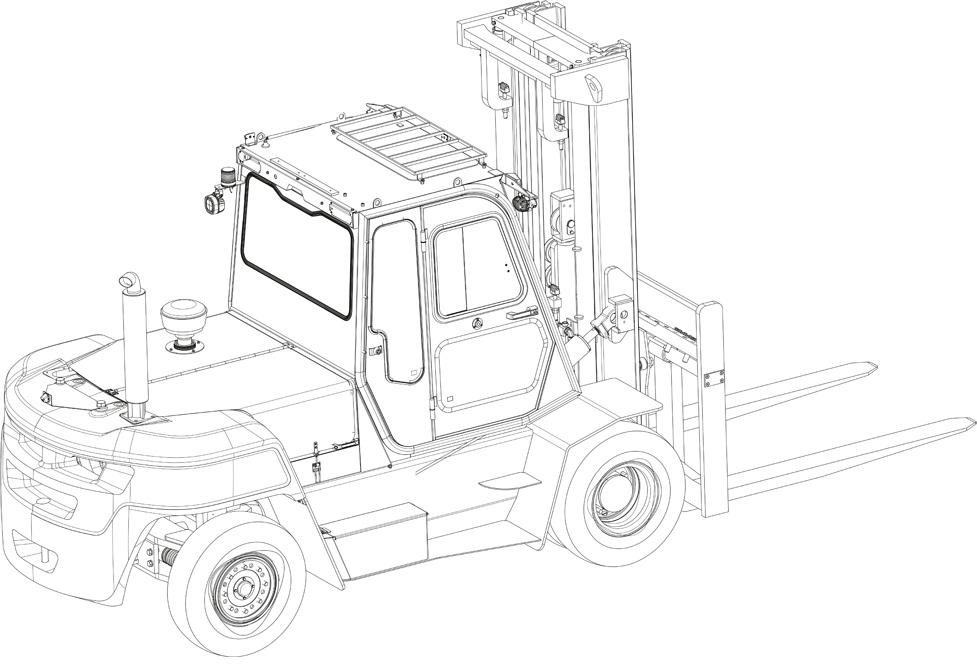

Forklift with diesel drive

Superelastic or pneumatic tyres

Capacity: 8000 kg @ 900 mm LC

C80D900

Overview

Developed for intensive heavy-duty applications. Low procurement costs without comprising on performance.

The load-bearing capacity of the C80D900 has been increased by 25% by reinforcing the frame, making the counterweight heavier and adapting the drive axle and the upright rails.

Ideal for demanding applications, such as in the construction industry, construction material yards, woodworking, metalworking industry, paper and beverages industry as well as at forwarding agents and logistics companies.

| C80D900 | 8000 kg |

Features

FROM WEATHER PROTECTION TO COMPLETE CAB WITH AIR CONDITIONING

Individual options ensure that adaptation to the respective application is possible. The C80D900 can be equipped with non-marking tyres, for example, acoustic reversing alarm, fork adjustment or integrated and projecting side loaders.

The cab can be extended by weather protection in the form of a roof and front window or fully equipped complete cabs. The two-piece driver’s doors can be opened by 180° and fixed to the chassis so that the truck can be driven with the door open.

The standard heated rear window as well as the easily accessible storage compartments and an MP3 radio round off the attractive driver’s workplace.

ALWAYS MOVING SAFELY WITH CLARK SAFEVIEW@360

The CLARK SafeView@360 is a 360° camera system that is made up of four digital cameras which give the driver a complete 360-degree view. Thanks to CLARK SafeView@360, drivers always have a great view of their surroundings. In addition, the use of digital cameras allows the images from the four individual cameras to be formed into a joint image in real time, enabling drivers to see the truck from the bird’s eye perspective. Especially the fork tips and the counterweight at the rear are precisely integrated into the seamless image. Thanks to this perfect, all-round visibility, drivers can navigate safely and quickly even in tight, unclear situations.

Highlights

STURDY CHASSIS “BUILT TO LAST®” DESIGN

Designed according to the “Built to last” concept, a sturdy and functional design with high-quality components is guaranteed. From the fully welded frame through the sturdy steering axle to the robust upright rails with a solid 8-roller fork carrier with four supporting rollers at the side.

LOW MAINTENANCE COSTS

Thanks to fault codes, simple on-board diagnosis is possible without expensive service tools being necessary. The hinged cover can simply be opened during maintenance work and the service technician thus has fast and comfortable access to all maintenance and wear parts.

SAFE LOAD HANDLING EVEN WITH HEAVY LOADS

The sturdy upright rails have solid 8-roller fork carriers with four supporting rollers at the side in order to be able to transport even off-centre loads reliably. The low-noise lifting hydraulics ensure gentle and quiet load handling of up to 8 tonnes with a load centre at 600 mm or 900 mm.

ERGONOMIC AND SAFE ENTRY AND EXIT

Drivers can reach their ergonomic workplace comfortably and safely thanks to two low, nonslip foot steps. The footwell is generously sized so that drivers have enough room, even if they are wearing safety footwear.

HYDRAULIC OPERATION

On request, ergonomic mini levers are available, control levers mounted on the hood are offered as standard. The pedals have an automotive layout, permitting intuitive operation

by the driver. Up to 5 additional functions are offered to adapt the truck to the respective application by means of attachments.

POWERFUL INDUSTRIAL ENGINES

This diesel engine guarantees powerful acceleration and reliable operation. The fully automatic three-speed transmission (“Power Shift”) fitted as standard ensures immediate

and jolt-free shifting and safe manoeuvring. Vibrations and noises are reduced to a minimum due to the disengagement of engine, transmission and drive axle.

-

STURDY CHASSIS “BUILT TO LAST®” DESIGN

Designed according to the “Built to last” concept, a sturdy and functional design with high-quality components is guaranteed. From the fully welded frame through the sturdy steering axle to the robust upright rails with a solid 8-roller fork carrier with four supporting rollers at the side.

-

LOW MAINTENANCE COSTS

Thanks to fault codes, simple on-board diagnosis is possible without expensive service tools being necessary. The hinged cover can simply be opened during maintenance work and the service technician thus has fast and comfortable access to all maintenance and wear parts.

-

SAFE LOAD HANDLING EVEN WITH HEAVY LOADS

The sturdy upright rails have solid 8-roller fork carriers with four supporting rollers at the side in order to be able to transport even off-centre loads reliably. The low-noise lifting hydraulics ensure gentle and quiet load handling of up to 8 tonnes with a load centre at 600 mm or 900 mm.

-

ERGONOMIC AND SAFE ENTRY AND EXIT

Drivers can reach their ergonomic workplace comfortably and safely thanks to two low, nonslip foot steps. The footwell is generously sized so that drivers have enough room, even if they are wearing safety footwear.

-

HYDRAULIC OPERATION

On request, ergonomic mini levers are available, control levers mounted on the hood are offered as standard. The pedals have an automotive layout, permitting intuitive operation

by the driver. Up to 5 additional functions are offered to adapt the truck to the respective application by means of attachments. -

POWERFUL INDUSTRIAL ENGINES

This diesel engine guarantees powerful acceleration and reliable operation. The fully automatic three-speed transmission (“Power Shift”) fitted as standard ensures immediate

and jolt-free shifting and safe manoeuvring. Vibrations and noises are reduced to a minimum due to the disengagement of engine, transmission and drive axle. -

LARGE COLOUR DISPLAY

The large colour display with access to maintenance and service settings provides information about all the important driving parameters. The temperature of the engines and transmission is monitored and the engine is switched off if necessary.

-

REAR-VIEW CAMERA OR 360° CAMERA SYSTEM

For working in the smallest of spaces and in critical areas in the warehouse, a rear-view camera or 360° camera system, the CLARK SafeView@360, are optionally available.

Residual load capacity

25 percent more residual load-bearing capacity with load centre at 900 mm

In order to increase the load-bearing capacity of the C80D900, relevant vehicle areas have been constructed even more solidly. Thus the C80D900 has a residual load-bearing capacity that is 25 percent higher at 900 mm load centre (without attachment) compared with the C80D with 600 mm load centre.

Equipment

-

PERFECT ALL-ROUND VIEW EVEN WITH TRIPLEX MASTS

PERFECT ALL-ROUND VIEW EVEN WITH TRIPLEX MASTS

The C80D900 stand out on account of their comparably slim lifting upright rails. In addition, the driver cab has large viewing windows to all sides. This gives drivers an excellent all-round view and unrestricted view of the load and fork carriers. This is possible thanks to the sophisticated arrangement of the chains and hoses on the upright rails. Clark uses double primary cylinders to ensure a good field of vision even when triplex masts are used.

-

LOW-MAINTENANCE WET DISC BRAKES

LOW-MAINTENANCE WET DISC BRAKES

Maintenance-free, wet disc brakes are installed as the standard service brake as well as an independent drum brake as the parking brake. This ensures gentle and smooth braking. Low brake wear guarantees a long service life and has a positive effect on operating costs.

-

SAVE COSTS – THROUGHOUT THE VEHICLE LIFETIME

SAVE COSTS – THROUGHOUT THE VEHICLE LIFETIME

Long maintenance intervals lead to short downtimes and low spare parts costs. The C80D900 offers maximum service friendliness. Maintenance-related components can be reached quickly and easily by the service technician.

The sturdy CLARK upright rails have a long service life. A full-flow return flow filter system filters the hydraulic oil every time it is returned to the tank. Coarse particles are filtered directly via a suction filter and do not even get into the oil circuit. This guarantees the durability of all hydraulic components. -

ERGONOMICS AND CAB

ERGONOMICS AND CAB

The tiltable steering column and comfortable seat can both be adjusted individually. Various driver’s seats, seatbelt monitor and an orange safety belt are available to choose from. An optional reversing grab handle with horn improves the rear view and goes easy on the driver’s neck and shoulders.

-

“POWER SHIFT” AUTOMATIC TRANSMISSION

“POWER SHIFT” AUTOMATIC TRANSMISSION

Simple operation is made possible by a fully automatic 3-speed transmission. The electronically controlled automatic gear shift makes comfortable and precise driving possible.

No further settings are necessary to guarantee precise work, even during the most difficult of applications. The inch pedal with integrated brake function makescontrolled driving and simultaneous fast lifting of loads possible. -

GOOD PRICEPERFORMANCE RATIO

GOOD PRICEPERFORMANCE RATIO

The CLARK C80D900 is equipped with as much sound technology as is necessary for heavy-moving, ergonomic and safe use.

Thanks to the selection of sound components and long years of experience in the construction of high-quality industrial trucks, a series with an excellent price-performance ratio has been created. -

A HIGH DEGREE OF SAFETY

A HIGH DEGREE OF SAFETY

The C80D900 has numerous safety functions:

- Temperature monitoring

- Additional lighting

- Blue LED headlight spot

- Seatbelt monitor and orange safety belt

- Transmission disengages when the

parking brake is engaged - Seat contact switch (Operator

Presence System (OPS)) - CLARK Vertical Mast System (VMS) for

vertical mast setting at the push of a button - CLARK SafeView@360 or rear-view camera

- Safety switch for attachments

Gallery

Video

Product video: Diesel forklift and gas forklift in use

Reliable in all tasks with high load capacities and powerful industrial engines.Experience our forklift trucks in action.