“The Forklift” from 1917 to 2017 – CLARK Material Handling Company celebrates 100 years in the forklift industry

A century of history

Duisburg, March 2017. CLARK will celebrate the 100th anniversary of the forklift in 2017. With its range of outstanding products and services, “CLARK – The Forklift” has been a leading supplier of in-plant logistics solutions since the first combustion engine-powered industrial forklift was invented in 1917 by American engineer Eugene Bradley Clark.Global manufacturer CLARK Material Handling Company offers customers and dealers a full range of combustion engine-powered and electric counterbalance trucks and warehouse equipment. In addition to the portfolio of machines, its selection of services and spare parts has also been significantly expanded over recent years. To coincide with the start of its 2017 anniversary year, CLARK has announced a centennial edition of the combustion engine-powered C20-35 series. The special edition with a capacity of 2.0 to 3.5 tonnes will be presented live on site by CLARK at the LogiMAT trade fair in Stuttgart on 14–16 March 2017 (hall 6, stand 6F41).

CLARK HISTORY

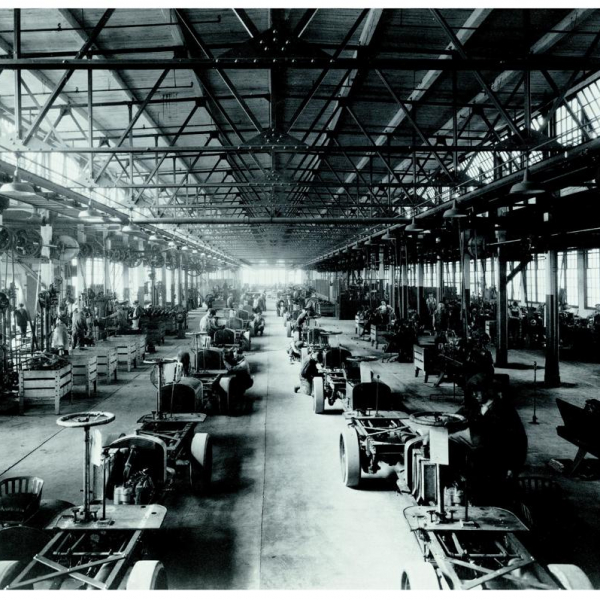

The Tructractor: looking back at the year 1917

Practical tasks need practical solutions. An ability to develop innovative solutions is the common theme running through CLARK’s 100-year history in materials handling, a story that began in Eugene Bradley Clark’s factory in Buchanan, Michigan, USA. The mechanical engineer and entrepreneur manufactured drills for the rail industry and steel rims and axles for cars. He sought an answer to the efficiency question of how to move materials from A to B more quickly and cheaply without the need for muscle power. More specifically, he wanted to transport sand and heavy loads of castings around the factory premises. A team of CLARK employees built a three-wheel platform truck with a cargo box for hauling loads of up to two tonnes. It was a strange vehicle – the steering was reversed and there were no brakes – but the “Tructractor”, as it was named, served its purpose perfectly. It was followed by the first petrol-driven truck, the Truclift, in 1920, before CLARK went on to launch the first forklift with a hydraulic lift, the Tructier, in 1928.

CLARK is synonymous with forklifts

Drive efficiency became a major focus in 1942,when CLARK built the Carloader, the first electrically powered forklift capable of working a full work shift. In 1943, the company was the first forklift manufacturer in the industry to attach warning and safety stickers to its vehicles. By then, the company had become so well-known that the name CLARK had become synonymous with forklifts, and it dominated the industrial truck market in the 1950s and 1960s. However, there was no slowdown in the pace of innovation. In 1952, CLARK expanded its portfolio to include driver training programmes,which had never been offered before. Another major advance in technology came in 1956, when CLARK developed the first nested upright with I-beams. This innovative design significantly improved the stability of the upright. 1967 saw two major successes, when industry leader CLARK introduced the first overhead guard as standard in all sit-down trucks. The company also developed and marketed the TW – the first highly manoeuvrable three-wheel electric forklift. In 1976, CLARK produced its 500,000th forklift – reaching the one million mark in 1997.

CLARK IN THE FUTURE

On course for further growth in 2017

“Of the more than 1.3 million CLARK forklifts produced since 1917, a good half is still in use. This underlines our claim of not only offering the best value for money, but also the most robust forklifts on the market,” said Stefan Budweit, Sales Director at CLARK Europe GmbH. The “built to last” principle is still proving its worth to this day, meaning that CLARK Material Handling Company remains one of the top ten forklift producers in the world. CLARK was acquired by parent company Young An of South Korea in 2003 and its global distribution network now consists of over 550 dealers in more than 100 countries on all continents. CLARK’s operational activities are managed at four headquarters around the world. With around 180 dealers, CLARK Europe GmbH serves the sales territory of Europe, the Middle East and Africa.

Range expanded to include warehouse equipment

“CLARK’s company history reflects the successful ongoing development of the forklift and its adaptation to the requirements of different industries and markets,” said Rolf Eiten, CEO of CLARK Europe GmbH, referring to the various forklift series with capacities of 1.3 to 8 tonnes in the product range. “Our expansion of the CLARK product range to include electric low lift pallet trucks, power stackers, reach trucks and electric tow tractors is also in line with our aim of anticipating trends and meeting the needs of the market – for end customers and dealers alike.” For example, the CLARK Compact range for the volume market, launched in autumn 2015, was extremely well received. The new CLARK generation includes electric stackers with a load capacity of 1.0 to 2.0 tonnes and electric low lift pallet trucks with a load capacity of 1.5 to 2.0 tonnes, with or without a platform, and with maximum travel speeds of up to 12 km/h. Rolf Eiten: “We plan to add further carefully selected machines to our range of warehouse equipment.”

New vehicles – high customer satisfaction

The new CLARK SRX14 and SRX16 (48 volt) reach trucks with load capacities of 1.4 to 1.6 tonnes and lift heights of up to 10.5 metres are also making a name for themselves. “They have become very well established in the market and the response has been extremely positive,” said Rolf Eiten, a year after the launch.“Our strategy of systematically developing new equipment and selectively optimising and expanding existing product groups shows that we have our finger firmly on the pulse of the market. The new CLARK GTS20-33 D/L forklift series also demonstrates that.” CLARK is currently developing new combustion engine-powered forklifts with a capacity of 2.0 to 3.5 tonnes, which are also aimed at the volume market. Rolf Eiten: “We are creating a completely new generation of machines, not simply giving existing ones a facelift.” CLARK is also planning to bring new electric three- and four-wheel forklifts (48 volts) onto the market in the near future. “The ever-expanding market for electric vehicles continues to offer considerable opportunities.”

A strategic outlook in 2017

CLARK Europe GmbH sees the expansion of its dealer network and stronger presence throughout the whole catchment area as one of its main strategic sales priorities. The company’s planned organic growth will begin at its European headquarters in Duisburg, which covers an area of 15,000 m². Acquired in 2014, it opens up a wide range of possibilities for CLARK by offering administration and training areas, workshop, spare parts store and forklift warehouse with more than 150 stock machines. “Over the last few years, we have met consistently high standards in terms of customer service, product availability and technical assistance,” said CLARK CEO Rolf Eiten. “The expansion of our spare parts business and the Totalift range with CLARK spare parts and OEM quality spare parts for other manufacturers’ equipment still offer considerable potential.”

Centennial celebrations in Lexington, Kentucky

In May 2017, CLARK employees from around the world will gather at the US headquarters in Lexington, Kentucky, to celebrate the company’s long journey towards becoming a global cult brand in the forklift industry, a journey that began with a single entrepreneur. The anniversary celebrations will take place at a location that is not only historically significant – it will also continue to be a prominent site for the company in the future. CLARK Material Handling is increasing production at the Lexington site by 200 per cent. In May 2016, the Lexington plant began producing the popular ECX electric four-wheel forklift and the TMX electric three-wheel forklift, both of which were previously produced at the San Luis Potosi plant. The Lexington plant will continue to produce the CLARK model series NPX, ESX, PWX and HWX. The expansion marks the first phase of CLARK’s global activities in North America, Brazil and Europe, which are scheduled for completion by 2020 and aim to increase existing production capacity 1.5 times. Dennis Lawrence, President and CEO of CLARK Material Handling Company, said: “The expansion of our production sites in North America puts CLARK in an even stronger position, offers dealers and users a secure future and provides job opportunities for local skilled workers.”

Gallery