Reach Truck

Capacity: 1400 / 1600 kg @ 600 mm LC

SRX14/16

Overview

_bearbeitet.jpg)

Are you looking for a solid reach truck and have high expectations?

We have the answer: CLARK’s SRX Reach Truck - including a wide range of standard configurations.

With high travel speed being standard (up to 14 km/h), support arm brake not subject to wear and tear and top safety features, CLARK reach trucks of the SRX series optimize productivity at your warehouse. The robust, reliable and high-performance reach truck by the inventor of the forklift was designed to meet even the highest expectations for the most sophisticated purposes.

| SRX14 | 1400 kg |

| SRX16 | 1600 kg |

Features

Comprehensive standard configuration

The SRX series has a number of standard configuration details enhancing safety and productivity when the equipment is in use:

- No-wear support arm brake

- Tilting Fork carriage

- High travel speed (up to 14 km/h)

- Upright with CLARK upright damping

- Electronic 180° or 360° steering

- Support arm rollers with protective guards

- Lateral battery removal via rollers

- Battery feed for easy maintenance

Why support arm brakes?

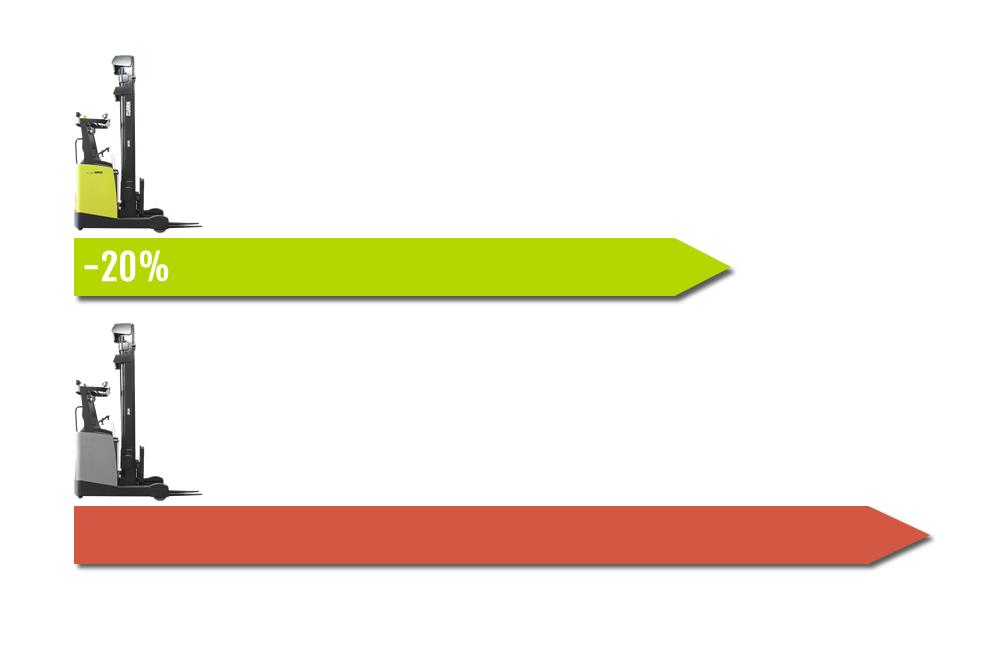

- 20% shorter braking distance due to support arm brakes as standard

- Shorter braking distance = improved safety

- Fast deceleration from up to 14 km/h travel speed in the warehouse, improves stock movement and improves safety.

Lithium-ion technology

The CLARK SRX14/16 reach truck is available with a 48-volt, 405 Ah lithium-ion battery for full performance and low maintenance. This enables intermediate charging of the Li-ion battery.

Around 10 per cent of the battery capacity is recharged in just 15 minutes. A full charge of the Li-ion battery is therefore possible in just over two hours.

Maximum visibility

- The overhead guard safety bars are in alignment with the driver’s line of sight

- Perfect visibility through the upright due to particularly wide upright bars

- Laterally rotated center cylinder

.jpg)

Ergonomics and driver's compartment

- Adjustable comfort seat

- Boarding height of only 380 mm due to low foot step

- Sensitive electric steering Adjustable Steering wheel position.

- Useful storage compartment

.jpg)

Easy safe handling

- Mini¬levers or mono¬joystick

- Hydraulics functions controllable simultaneously

- 180° or 360° steering

- Deceleration when cornering

- Spacious and excellent visibility

Productivity and energy efficiency

- Customized programming of operation to suit all applications

- Maximum adjustment to each work situation

- Large clear operators display

- All settings and functions at a glance - adjustable without special software

Reach trucks with wide chassis version

- Extends the possibilities for transporting various transport aids.

- Optimally suited for the transport of industrial pallets with a width of 1000 mm

- Increased distance between support arms of 1100 mm (b4)

Highlights

High capacities and high lift heights

Robust structure and stability Nested I-sections The upright rails with an I-section show a 55% higher torsional rigidity than common flat profiles Lower deformation even when under lateral pressure.

Result:

Durability and stability are enhanced - even at high lift heights.

Maximum visibility

Overhead guard

The overhead guard safety bars are in alignment with the driver’s line of sight.

Maximum visibility

Visibility through the upright.

Maximum visibility through the upright thanks to particularly wide upright bars and a laterally rotated center cylinder.

Useful options available

Zum Beispiel:

Fork camera with monitor for safety and high throughput rate.

-

High capacities and high lift heights

Robust structure and stability Nested I-sections The upright rails with an I-section show a 55% higher torsional rigidity than common flat profiles Lower deformation even when under lateral pressure.

Result:

Durability and stability are enhanced - even at high lift heights. -

Maximum visibility

Overhead guard

The overhead guard safety bars are in alignment with the driver’s line of sight. -

Maximum visibility

Visibility through the upright.

Maximum visibility through the upright thanks to particularly wide upright bars and a laterally rotated center cylinder. -

Useful options available

Zum Beispiel:

Fork camera with monitor for safety and high throughput rate. -

Mast damping

Gently move loads.

Gentle lifting and lowering due to integrated hydraulic damping system Soft transition between upright rails No loud banging when lowering Increases durability of the components. -

No-wear support arm brakes

Enhanced safety as a standard configuration.

Two no-wear support arm brakes provide efficient braking each time brakes are deployed. Unlike in drum brakes, the brakes do not require any maintenance.

Equipment

Automatic horizontal fork positioning

Suitable in particular for large lift heights No unsafe estimates of fork angles

Automatic side shift centering

Safe and easy handling, Speeds up positioning on the shelving units.

Lift height preselector

Fork stops automatically at the desired lift height, Improved throughput rate due to faster positioning Decreases load damage or damage to the shelving system

Fork positioner

Easily stores cages and different loads Accelerates transportation of goods of different dimensions.

Battery compartment sizes

Three capacity options (465/620/775 Ah) Standard lateral battery removal

Mini-levers or mono-joystick

100% proportional lifting and lowering with Ergonomic armrest

Activation using PIN code

Activation without an ignition key by using four-digit PIN code Configuration settings include automatic shutdown.

Fork camera and monitor

Improved ergonomics. No need to look up to the merchandise. Quicker access to higher shelving units. Noticeable relief for the driver.

Gallery

Video

Product video: Reach truck in action

Discover numerous advantages and options, such as the fork camera and the automatic horizontal position of the forks, which ensure that the CLARK reach truck can be customised precisely to your requirements. Find out more about these benefits in our product video:

_bearbeitet-de8954ce3dd47885822c1158600a275a.jpg)